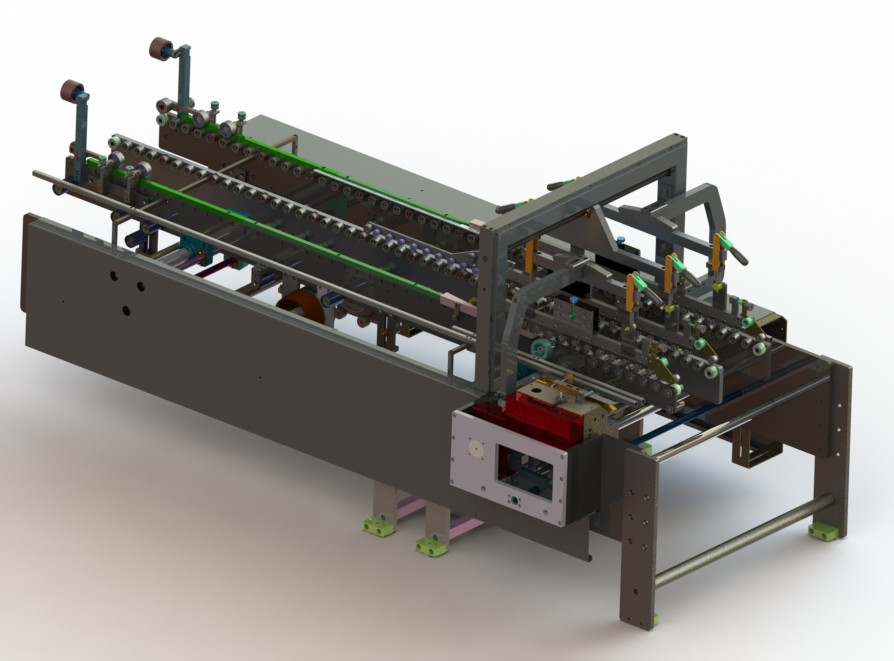

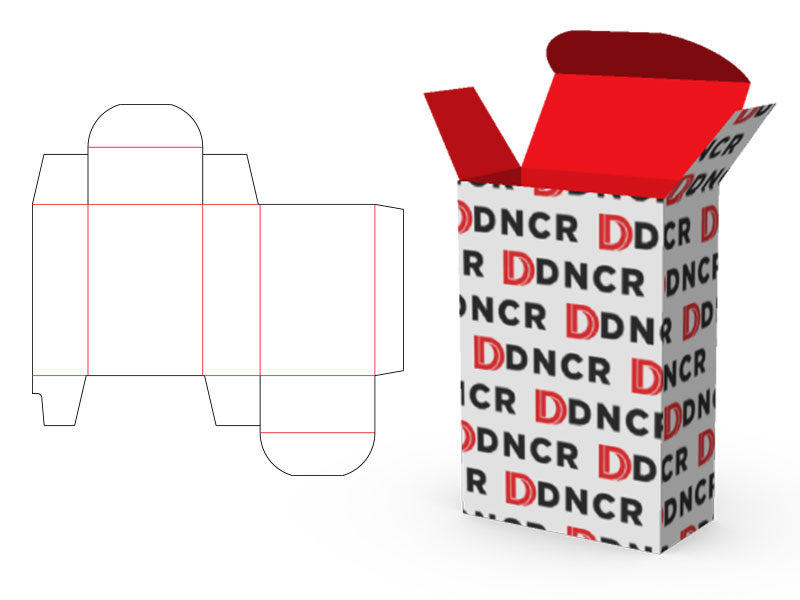

DINCER 90 (3 and 4 POINTS) SERIES

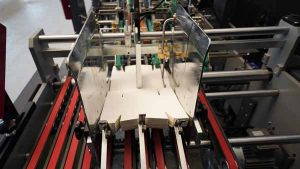

BOX FOLDER AND GLUER MACHINE

INTRODUCTION VIDEO

MACHINE SECTIONS AND TECHNICAL SPECIFICATIONS :

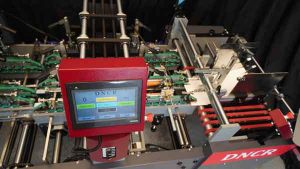

ELECTRIC-ELECTRONICAL AUTOMATION SYSTEM :

- Seperate electrical cabinet containing all the electrical equipments and components

- Siemens automation control system S7-1200 PLC

- KTP-700 ( 7”) Siemens touch screen where all the machine functions can be reached

- 1 piece remote control

- Push buttons at the feeder, delivery and stacker sections

- Programmable alarm horn for safety.

- 4 pieces synchronized AC motors and Siemens drivers (V20 Serie)

- Belt speed: 400 m/min.